Product Information

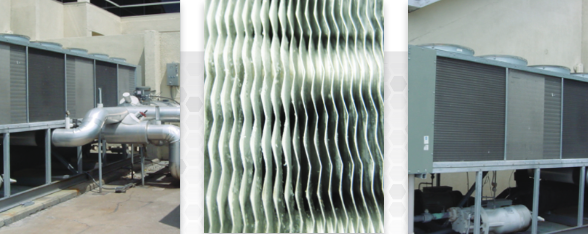

MicroGuard® is an advanced, inert, inorganic, oligomeric, siloxane coating that cures at ambient temperatures. The cross-link cured deposits produce a glass-like film that creates an ultra-thin, micron-depth layering of inorganic crystals, forming a homogenous inter-linking network that chemically bonds to non-ferrous metals and painted surfaces.

MicroGuard® coatings use both atom-to-atom covalent bonding and London Force bonding to form one of the most durable coatings available.

MicroGuard® is patented and superior to traditional HVAC/R coatings in that it withstands the damaging effects of chemical abuse, abrasion, and ablation, intense heat, ultra-violet light, and corrosive degradation. The clear coating enhances and maintains a unit’s natural surface appearance without distortion.

Benefits of MicroGuard1 3500 coating for HVAC

- Exceptional salt and acid corrosion protection withstanding over 20

- 300 hours of salt chamber testing and still going!

- Enhances laminar airflow and increases a unit’s lifetime energy efficiency (EER) by up to 15% resulting in lower operating costs and a reduction in up to 60 pounds of NOX/CO2 emissions per ton per year

- Will not reduce heat transference

- An inorganic material that inhibits the growth of mold and mildew

- Reduces maintenance costs enabling the cleaning of units with a mild

- eco-friendly degreaser and water

- Very low VOC’s